FläktGroup SEMCO chilled beams create an exceptionally comfortable indoor environment. Often used in lieu of fan coil units, chilled beams offer even air dissemination that avoids pockets of concentrated air. Chilled beams send fully mixed air evenly throughout a room to provide overall comfort with the right temperature and humidity.

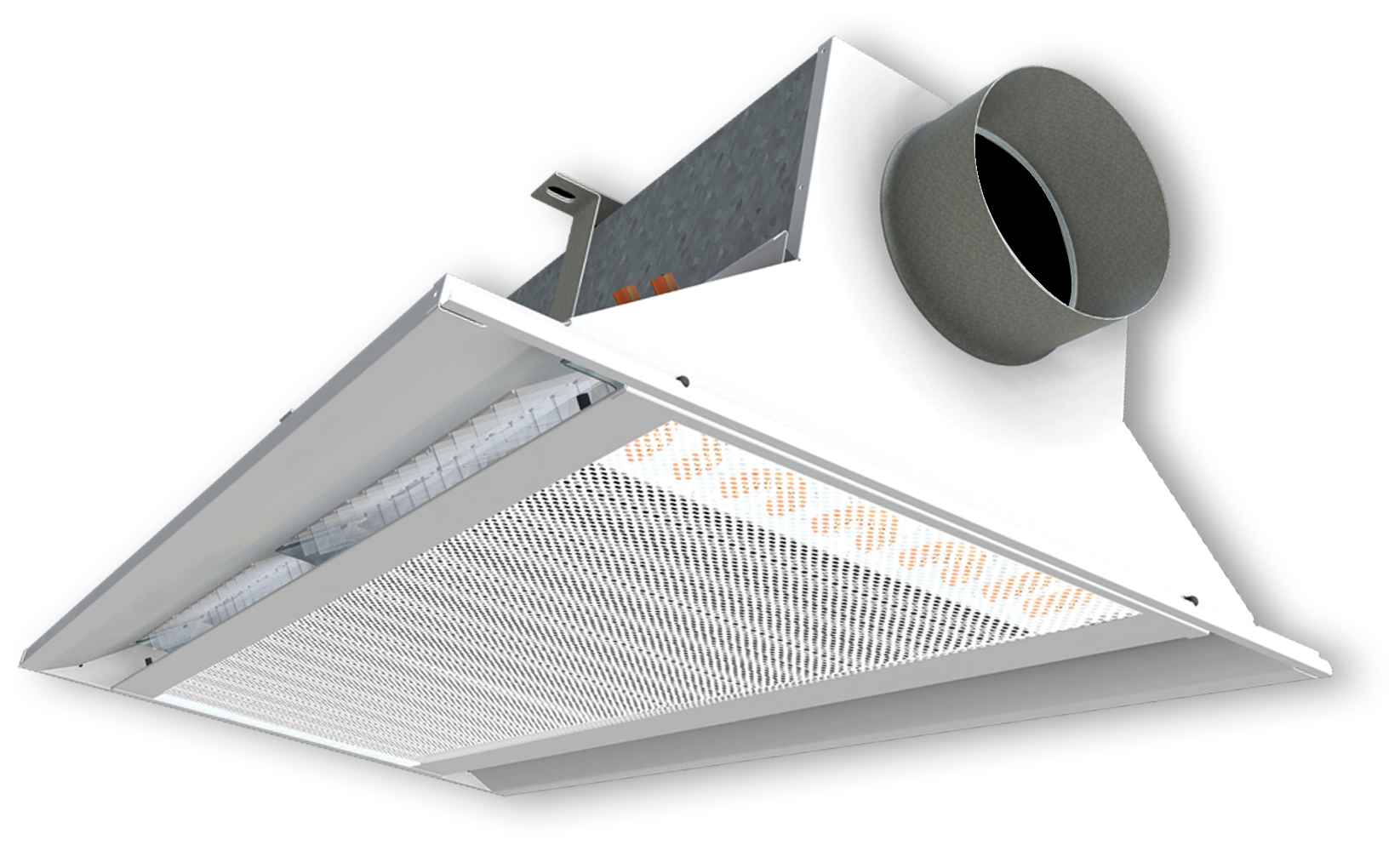

Manufactured in the United States, the Juno IQHC is an active chilled beam that has the best-in-class cooling capacity with the lowest air and water drop. It also provides a lower noise level than most HVAC alternatives and offers a simple, flexible installation.

FläktGroup SEMCO's Juno IQHC is a universal beam. A universal beam design minimizes concerns related to duct location, water location, nozzle set, duct size, and more. It ensures that contractors minimize time sorting to find the exact beam for each specified room and location. The Juno IQHC has multiple sizes for primary air inlets and discharge air slots to handle a broader range of ventilation pressures and flows. In addition, FläktGroup SEMCO’s solution streamlines and simplifies the process and reduces errors. The Juno is available with cable or rigid suspension. These beams feature optional threaded connections and hose kits allowing installation without soldering and associated hot work permits or fire watch after rough-in. The Juno can be installed in U.S. ceiling grids or drywall ceilings. Our improved dry-wall trim kit allows for a clean edge around the beam improving the finished look after installation in rooms without lay-in ceilings.

FlaktGroup SEMCO makes it easier to select and review your options, sound, and performances with our new in-house, web-based selection tool.

Active chilled beams such as the Juno, work together with the Pinnacle and the Neuton to provide one energy-efficient system known as 3fficiency.

FläktGroup SEMCO Chilled Beam Brochure

Juno IQHC Features and Benefits

Why Specify the IQHC Active Chilled Beam

Pinnacle and Chilled Beam Application Guide

Chilled Beams in the News

Outdated Factory Tranformed into LEED-Certified School - ACHR The News

Active Chilled Beams - ACHR The News

Chilled Beams Use Less Pump Energy - Retrofit Magazine

Active Chilled Beams for Green Commercial Buildings - Facilities Net

SEMCO Introduces Active Chilled Beams with Reduced Pump, Fan Energy - Energy Manager Today

Find the instructions for the chilled beam selection tool here.

Use the button below to access the selection tool on the FläktGroup website.

The Neuton® Controlled Chilled Beam Pump Module is an innovative, award winning pump module that provides active condensation control effectively addressing one of the key design concerns regarding active chilled beams. Learn more about the industry’s first smart, plug-and-play controlled chilled beam pump module for reducing chilled beam system installation and operational costs.

© 2020 FläktGroup SEMCO. All rights reserved. SEMCO® is a registered trademark of SEMCO, LLC and SEMCO Duct and Acoustical Products, Inc. SEMCO, LLC and SEMCO Duct & Acoustical Products, Inc. are part of FläktGroup and are sometimes referred to collectively as FläktGroup SEMCO © 2020 FläktGroup SEMCO. All rights reserved. SEMCO® is a registered trademark of SEMCO, LLC and SEMCO Duct and Acoustical Products, Inc. SEMCO, LLC and SEMCO Duct & Acoustical Products, Inc. are part of FläktGroup and are sometimes referred to collectively as FläktGroup SEMCO